WWW.ENGINEERING-UPDATE.CO.UK June 2023 Sponsored by

ENGINEERING PDATE

At the forefront of digital marketing, Engineering Update strives to bring the latest in industrial engineering in a format that provides the best usability and ease of use for our readers.

Publication Director

Jodie Little

01843 595818

jodie@jetdigitalmedia.co.uk

Editorial Assistant

Laura Sharpe

01843 448 443

laura@engineering-update.co.uk

Editorial Assistant

Leigh Little

01843 448 443

leigh@engineering-update.co.uk

Publishing House

Jet Digital Media Ltd, Suite 1 & 2 Spratling Court Offices, Spratling Street, Manston, Kent CT12 5AN

Editor’s Comments

Welcome to the June issue of Engineering Update!

With summer on the not so distant horizon, I hope that everyone is in good health and looking forward to longer, and most importantly, sunnier days ahead.

As well all know, the Engineering industry never stops continuing to research, develop, and produce new technologies and solutions for our ever-changing world, and this month is no different.

From a group of scientists at Oxford University working on new graphene based batteries that look to revolutionise the way we charge and store energy within our devices. To the exciting news of a new research centre for robotics and artificial intelligence that is set to be opened at the University of Birmingham. Engineering Update’s June issue is packed full of the latest news, products, and services from some of the industry’s leading authorities on Engineering innovation.

We are always keen to hear the thoughts and insights of experts within the industry and welcome submissions for upcoming issues.

If you have any knowledge to impart, please get in touch!

Jodie Little - Publications Director jodie@engineering-update.co.uk

www.engineering-update.co.uk

Jodie Little

WWW.ENGINEERING-UPDATE.CO.UK June 2023 Sponsored by ENGINEERING PDATE

CONTENTS

The next level of modular industrial connectors 10 Easy product handling with vacuum belt conveyors 14 |3 Electric car giving driving lessons to children 22 Ruggedized lenses for space projects 16 Taking drive performance to the next level 21 June 2023

REMBE® Pressure Relief and Explosion Safety. © REMBE® | All rights reserved rembe.com hello@rembe.com

50 years of REMBE With empathy and heart, at any time and worldwide

After fifty years of business, people often look back at the history, at old pictures, brochures and reports. But in REMBE’s anniversary year things are different, because here (today just as 50 years ago) it is the people who shape the corporate spirit and make REMBE what it is today.

Stefan Penno, Chief Executive Officer REMBE GmbH Safety+Control explains: “We trust each other, see the best in people and believe in each person’s individual strengths. Because humans are what matters to us.”

Bernhard Penno founded the company in 1973 as a sales office for rupture discs – initially as a one-man business in his garage at home. Just a few years later, new rupture disc designs were being manufactured in the company’s first production hall. In 2005, Stefan Penno, the son of the company founder, took the reins of the business. Today, REMBE employs 340 “RFM” (REMBE family members) in over 90 countries and with 10 subsidiaries.

To mark its anniversary year, REMBE has come up with some “special activities” . This year’s celebrations are entirely in keeping with the above motto. They will start with an international REX conference for all RFMs worldwide. After a long break due to the coronavirus pandemic, the conference can finally resume this year at the newly renovated company headquarters in Brilon, Sauerland. This will be followed by the REMBE Family Day, thus ensuring that the anniversary year will be commemorated in style.

REMBE rupture discs and explosion protection systems safeguard processes in all industries around the world and help to save lives every day. REMBE wouldn’t be REMBE if we didn’t think outside the box, says Stefan Penno. With this in mind, several initiatives have been launched in

recent years. For example, the RFMs involved in the REMBE green initiative are looking for improvement potential, determining which environmental aspects could be given greater attention to benefit customers and partners, and evaluating ways to ensure natural resources are handled responsibly – and are thus making a small contribution to protecting our planet.

After the REMBE WeltWald was launched last year as a major project of the initiative (8 hectares of forest are being reforested here), there is another campaign for the anniversary. 50 years - 500 trees.

For more information: https://rembe-green.de/

|5 June 2023 ENGINEERING PDATE

SICK’s multiScan Masters Precision 3D LiDAR Navigation and Collision Avoidance

SICK has unveiled a milestone advance in its three-dimensional LiDAR technology with the launch of the multiScan multi-layered LiDAR sensor.

The SICK multiScan combines floor-toceiling 360° environment perception with high-resolution navigation for reliable realtime localisation, mapping and collision avoidance in automated mobile robots (AMRs) and industrial vehicles.

Developed on the foundations of SICK’s industry-leading multi-echo LiDAR technology, the SICK multiScan is a compact, lightweight and rugged 3D sensor designed to maximise vehicle availability in both indoor and harsh outdoor environments. With their broad 360° x 65° field of view and 16 scan layers, the LiDAR sensors in the multiScan100 family use on-device preprocessing to output a dense 3D point cloud with 690,000 measuring points, complemented by a high-resolution 0° 2D scan plane for precision navigation.

Online Specification

Each multiScan arrives factory-calibrated and ready for use, whether it is specified as a standard pre-configured product or using the specially-developed Online Configurator. Machine builders and integrators can select the features they need for their application using the timesaving online platform with access to software apps and add-ons for easy customisation.

“Designed with the needs of integrators in mind, the multiScan’s ability to preprocess precision measurement data in real time with no external controller sets it apart,” explains Nathaniel Hofmann, SICK’s Market Product Manager for Measurement Systems.

“The multiScan provides a detailed 3D point cloud of its environment, so the AMR knows exactly where it is, and where any objects are, and it can update its 3D map as it travels around. At any moment in time, it is providing real-world measurements of the production floor or warehouse to make the AMR as efficient and available as possible.”

To enhance the 16-layer 360° horizontal coverage, the multiScan’s vertical aperture angle is configured to optimise the layers between -22.5° to +42.5°. This ensures reliable collision avoidance for objects at ground level, as well detecting cliff edges and ramp inclinations. Objects protruding into the field of view at height, e.g. on warehouse shelving, can also be reliably avoided. The multiScan136, the first sensor to be launched in the product family, has a 360° x 65° field of view and a 60m working range with further variants available from later in 2023.

On-the-Spot Troubleshooting

The multiScan can also be used with SICK’s Augmented Reality Assistant, SARA for troubleshooting and configuration of LiDAR sensors on Automated Mobile Robots. Diagnosis and correction of machine downtime, such as a field infringement, can be done ‘on the spot’ with a mobile phone, without the need to connect a PC.

The multiScan100 family achieves high performance and availability in harsh industrial environments, with a choice of rugged housings available up to IP69K. Using SICK’s unique multi-echo LiDAR technology, the multiScan generates three echoes per beam at 20Hz to achieve higher availability by filtering out the false signals caused by unwanted laser reflections from raindrops, snow, fog or dust particles.

Online Configurator

With SICK’s Online Configurator, engineers are prompted to make selections to customise the multiScan for its working

environment, with the opportunity to select hardware options and software add-ons.

In addition to the standard sensor software for data streaming, customers can also select feature add-ons, e.g. for reflector recognition, data reduction and pre-processing, or a filter package where additional robustness is needed e.g. outdoor weather or harsh industrial conditions. Specialised pre-developed SICK sensor apps, such as Safe Break Assist and the SICK LiDAR-LOC are also available to use with the multiScan.

Equipped with 100Mbps Ethernet, eight multifunctional I/Os and matching system plugs, the SICK multiScan is easy to integrate and saves engineers valuable time during commissioning. When ordering, customers can select predefined parameters or choose previously stored configurations. SICK imports them onto the device before delivery. www.sick.co.uk

June 2023 8| ENGINEERING PDATE

Supply Chain Stability

Many businesses are continuing to report lengthy lead times, unexpected customs charges and high shipping costs. Sourcing fasteners from or nearer to point of manufacture has become a clear way for businesses to bypass common supply issues, by significantly lessening both transportation cost and time to redelegate funds and meet demand. Localised sourcing also brings with it more fruitful and communicative customer-supplier relationships, allowing for increased visibility over processes and delivery.

Sustainability

Spurred on by both consumer and government demands for eco-friendly products and processes, manufacturers are also onshoring and nearshoring fasteners to limit their carbon footprint. Fastener sourcing is often one of the first stages of a production build and, with goods transportation amounting to 17% of the world’s greenhouse gas emissions, eco-friendly procurement is becoming a crucial first step in many manufacturers’ sustainability roadmaps.

Optimas Solutions, the leading global industrial distributor of fasteners and supply chain solutions, are just one such company to have seen an uptick in the amount of customers looking to onshore and nearshore their fastener supply.

With cold-form manufacturing facilities on both sides of the Atlantic, Optimas facilitate a considerable number of US, UK and European customers to meet their sustainability targets and reduce their supply chain risk.

Eco-Friendly Manufacturing

Cold-form manufacturing is a process with a substantial amount of history - first records of its use date back to the 1800s - but the team have proved its suitability to multiple

Onshoring and Nearshoring: Reassessing Supply Chains

As global conflicts and rising inflation encourage many manufacturers to reassess their sourcing processes, the last year has seen a myriad of UK and European businesses looking to onshore and nearshore their fastener supply. However, localised sourcing appeals not only to those looking to mitigate supply chain risk, but to the plethora of manufacturers aiming to lower their carbon footprint.

modern engineering requirements. The company recently secured a partnership with a notable electric vehicle business with facilities across the UK and mainland Europe, cemented by their ability to source and manufacture fasteners close to the end-user. The facility also caters for those with design and rapid prototyping requirements, boasting state-ofthe-art industrial 3D printing and CNC turning machines.

As 2023 looks set to present a continuation of supply instability, onshoring and nearshoring opportunities will continue to play a crucial role in helping manufacturers meet demand.

|9 June 2023 international.optimas.com

The next level of modular industrial connectors

Manufacturing and engineering continue to evolve quickly as new machinery becomes ever more intelligent and adaptable to meet customer demands. Connectors are a vital element of this evolution as they offer flexibility, security, and durability to users. HARTING produce robust industrial connectors and their latest products deliver future-proof solutions to their customers.

When Han-Modular® was first released back in 1993, it was the first modular industrial connector to run power, signal, and data alongside each other in a single connector. Now the next development stage of the modular connector is upon us with the launch of the new HanModular® Domino range, which offers space savings of up to 50%, compared to existing designs.

Just as dominoes have two separate squares, a domino module is made up of two building blocks or ‘cubes’. The Han-Modular® mating face is divided in two, resulting in an almost square surface in which even larger contacts can be accommodated.

These cubes allow users to configure customised connectors which are exactly tailored to their design requirements. Power, signal, data or compressed air can now be combined in one module, reducing the total number of interfaces required. As a result, assembly areas which are difficult to reach can be equipped more efficiently or even opened up for assembly in the first place.

With the addition of the new Domino range there are now over 250 modules to choose from and many thousands of potential combinations available, increasing design

flexibility. The new Domino modules are also compatible with standard components of the Han-Modular® series.

Another modular range which delivers time-saving benefits is Han-Eco®, a series of hoods and housings available in a variety of designs including bulkhead, surface mount, and cable-to-cable.

The main advantage of using Han-Eco® is the time-savings that can be achieved by rear mounting inserts in control and switch cabinets. Engineers no longer need to install cables through the bulkhead mounted housing before assembling the contact inserts. Instead, pre-assembled inserts are directly snapped into the housing from the rear, simplifying assembly and saving time.

Han-Eco® housings are compatible with both monobloc and modular inserts, giving you an unparalleled choice of data, signal and power options. Furthermore, HanEco® is entirely compatible with standard metal Han® housings, meaning both variants can be integrated into your production equipment.

To learn more about HARTING’s range of connector solutions, please visit www.harting.com or email your query to salesuk@harting.com .

10|

The next level of modular industrial connectors.

Han-Modular ® Domino ModulesRobust technology for industrial transformation.

The first modular connector with a hybrid module configuration

■ Smaller and lighter connectors allow space savings of up to 50%

■ Compatible with components of the Han-Modular ® series, the market standard for modular industrial connectors

■ Flexible and scalable to the respective need

■ Sustainability through consistent modularisation

■ Reduction of installation times by combining several individual connections

One Range. No Limits: www.HARTING.com/domino

TR launches new products to its Plastics & Rubber Hardware range

TR Fastenings, part of the Trifast group of companies, is expanding its product portfolio with the addition of 1500 new part numbers being added to the existing Plastic & Rubber Hardware range. This is in response to product requests across all sectors including automotive, health and home and energy, tech, and infrastructure.

With this rising market demand combined with technical support on new innovative plastic materials, TR has embraced the opportunity to work with design teams across different industries with varying application requirements. TR’s strength is in the fast turnaround of prototypes and short lead time support on tooling, giving TR engineers a leading edge when involved in early engagement design projects.

The automotive industry in particular has experienced the biggest surge in growth with the use of plastic components over machined metal parts, mainly driven by the continued global momentum of electric vehicle production. Automotive manufacturers are looking at

using plastics as base materials to build automotive parts due to their lightweight properties which can be 30% to 50% less compared to metal.

Andrew Fletcher, Director of Plastics and Rubber (Commercial and Technical) at TR commented: “We remain fully committed to offering our customers the very best in plastic components with our continuous product developments. It’s more than just delivering a product, it’s about design, development and collaboration; we’re here to provide solutions and we’re perfectly placed to react quickly to the changing marketplace.”

For more information on TR’s Plastic & Rubber range please click here

TR’s top new product ranges and their application uses include:

Screw Rivets provide a fastening that is simple to use and is removable, making them ideal for applications where maintenance or servicing via a removable panel is required. For automotive applications they are used in splash guards around wheel arches, internal upholstery, and bumper assemblies. Screw Rivets also find applications in domestic appliances, marine, audio equipment and furniture fittings.

Barbed Push-in Rivets , also known as Fir Tree/Pin Tree Clips are designed to secure two panels together. They are easy to install with a simple push-fit action. In automotive the are used in wheel arch bumpers, splash shields, bumper assemblies, internal upholstery, and trim. Other applications include domestic appliances, furniture and electrical/electronic equipment.

Kwik Nuts are designed to push fit onto a threaded stud then turned through 180° to secure in place, allowing a tool free rapid installation. Automotive applications include vehicle acoustic engine liners and interior assemblies. Other applications include air conditioning and ventilation equipment.

Push Screws are a new product which combines the rapid installation of a Fir Tree Clip with the versatility of a conventional threaded screw. The part is designed to push fit and retain in a female thread, then be removed with a standard screwdriver. The part enables rapid tool free installation with pull out forces ranging from 50N (M3) to 210N (M8) making them ideal for decorative trims, seat trim panels and mounting brackets.

Shockproof Snap Rivets is a new development and an improvement on the standard design of a Snap Rivet. The design incorporates a locking mechanism under the head which resists pin movement when subject to mechanical shock or vibration, making them ideal for automotive interior applications, industrial lighting, pumps, heating, and ventilation. Heat resistant options are also available for applications where operating temperatures of up to 190°C are required.

June 2023 12| ENGINEERING PDATE

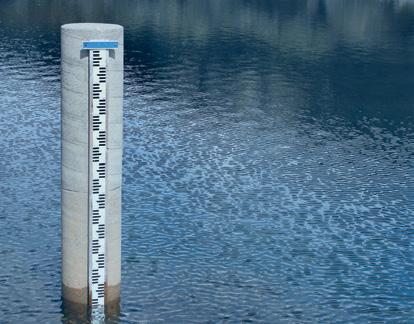

Flow Measurement of High Viscosity Liquids

Positive Displacement flow measurement devices, such as Titan Enterprises’ Oval Gear (OG) flowmeters , are one of the most widely used types of flow meter for measuring the flow of petroleum liquids and petrochemical additive injection fluids. They remain a solid choice for many applications in today’s modern process control environment, due to the OG’s suitability in harsh environments, high-pressure capability, and long-term reliability with minimum maintenance. They are also ideally suited for viscous fluids.

High viscosity liquids, such as fuels, thick oils, bitumen, resin and tar, require devices that are precision engineered to provide highly accurate flow measurement. The teeth in an oval gear meter are used to drive the gear and seal the central path, with the differential force being developed by the shape of the ovals rather than the gear teeth on the lobe. Oval Gears vary in size and shape depending on the resolution and flow requirement of the process application.

The pressure drop is essentially the limiting factor when it comes to metering high viscosity liquids within an application. The Oval Gears within these flow measurement devices provide a larger surface area generating a much greater driving pressure across the gears. This results in a wider flow range capability and lower pressure drop (see graph below) compared to other positive displacement meter types.

Neil Hannay, Titan Enterprises’ Senior Development Engineer, says: “The higher the viscosity of a liquid, the more pressure will be required to ‘force’ the liquid into the flowmeter and around the oval gears. It’s important to bear this in mind when selecting the correct size of oval gear flowmeter for your application. For example, more pressure will be required to push through resin than diesel.”

Almost immune from the effects of varying liquid viscosity, density and temperature, the measurement accuracy of Titans’ Oval Gear (OG) flowmeters improves as liquid viscosity increases, from a nominal 1% to around 0.1% of flow rate at higher viscosities. Titan’s standard OG models provide high accuracy up to 1000 cSt; for viscosities above 1000 cSt Titan’s specially profiled gears are supplied to facilitate additional flow of the liquid.

Titan Enterprises offer special options and adaptive designs of its Oval Gear meters to meet specific highpressure requirements, aid chemical compatibility, and ensure safe operation in potentially explosive atmospheres. Titan’s Oval Gear range of meters include ATEX compliant IP65/NEMA 4 protection models, and devices that offer intrinsically safe options for processes that operate within harsh environmental conditions, such as explosive or corrosive atmospheres, where flowmeters are required to withstand tough environments whilst maintaining accurate and reliable measurement.

Titan’s Oval Gear meters can be pressure tested in-house up to 950 bar for custom-designed models and calibrated against diesel upon request. In the chemical industry, oval gear flowmeters are often used in conjunction with a batch controller to allow for the automatic dispensing of pre-set volumes of chemicals.

For further information on the full range of Oval Gear flowmeters or to discuss your specific OEM application, please contact Titan Enterprises on +44 (0)1935 812790, email sales@flowmeters.co.uk or visit our website

|13 June 2023 ENGINEERING PDATE

There are few industries as demanding as the chemical and petrochemical industry when it comes to liquid flow measurement and control.

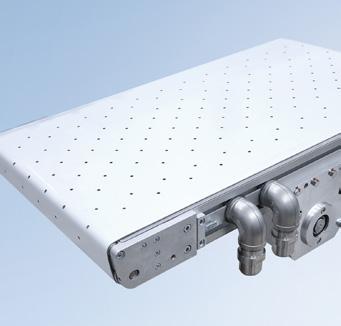

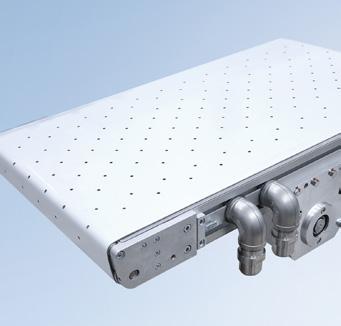

EASY PRODUCT HANDLING with Vacuum Belt Conveyors

Belt conveyors with vacuum function for conveying goods in fixed positions without gripping or pallets.

Do your products tip over or float on the belt conveyor at high accelerations? Do your short cycle times not allow you to stop and handle the products with a gripper? Do you want to coat, scan, label or laser your products on their base? Do your products have to be continuously elevated or bridge a gap?

When transporting with a vacuum belt conveyor, products are fixed to the belt conveyor by a vacuum. This means that the products can, for example, be accelerated quickly or transported vertically, overhead or alongside the conveyor. Intermittent handling tasks can also run continuously with vacuum belt conveyors.

Vacuum belt conveyors are typically used to secure lightweight/largearea products at high accelerations or speeds. Goods of this type are often transported in the packaging, consumer goods and paper industries, or in battery production.

mk offers all of its belt conveyors and timing belt conveyors as vacuum belts. Only the conveyor frame and

the belt are modified to implement the vacuum function. Unlike the belt conveyor, the timing belt conveyor has a positive drive mechanism that allows it to run without slippage. If an image processing system is used, the individual images can be matched to a specific distance travelled.

Our engineers will design all the necessary components, from the belt conveyor and suction line to the pump. Alternatively, you can request a complete vacuum belt conveyor that you can integrate into your production environment.

Benefits of the vacuum belt conveyor

• Fixed position transport without gripping or pallets

• Secure transport of lightweight products at high accelerations – no tipping over or floating

• Products can be transported overhead or alongside the conveyor

• Products can be processed or checked while moving

Basic structure of a vacuum belt conveyor

The conveyor frame is equipped with suction fittings for a vacuum pump (e.g. industrial vacuum cleaner or side channel blower). This creates a vacuum inside the conveyor frame. The conveyed products are gripped through holes in the slide bed and in the belt located above it, and then conveyed with the belt.

To find more contact mk Profile Systems on (01949) 823751, email info@mkprofiles.co.uk or visit www.mkprofiles.co.uk

14 June 2023 ENGINEERING PDATE

Vacuum Belt Conveyor

Easy Product Handling with Vacuum Belt Conveyors

Fixed position transport without gripping or pallets

Secure transport of lightweight products at high acceleration

Products can be transported overhead or hanging alongside the conveyor

Products can be processed or checked while moving

www.mkprofiles.co.uk

mk Profile Systems Limited a company of the mk Technology Group

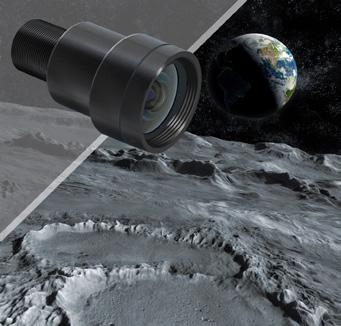

Ruggedized Lenses for Space Projects

Resolve Optics is a leading designer and international supplier of ruggedized lenses and optical systems for spaceborne applications.

The cost of launching payloads into space is considerable, incorporating only ‘space ready’ ruggedized lenses or optical systems into your satellite or space observation system is therefore critical for achieving longer term, highperformance operation.

During launch into space - lenses in high precision instruments and cameras are subject to vibration and shock. While slight vibration might cause malfunction in lenses, severe vibration can result in damage that is beyond repair. Shock waves are also highly detrimental to the performance and operation of high precision optical devices.

To minimize the effects of vibration and shock it is advisable to keep your optical components small and light. The less mass you have the less effect vibration and shock will have. To stop components in your optical system from moving requires that all parts are retained as tightly as possible and that retaining rings cannot work loose. This can be done by staking the retaining rings so that they cannot come loose. However, if your required optical components are heavier then it may be preferential to bond all the elements in position. Consequently, the mechanical design of space ready optics must consider the mass of the elements and determine what method of retaining is required. Also, importantly, the effects of vibration and shock must be considered across the operating temperature range

of space launch to ensure optical components cannot become loose due to temperature cycling.

Over the last 20 years - Resolve Optics has developed the expertise to design ruggedized lenses and optical systems proven to withstand the vibration effects and shocks encountered during launch. To ensure all ruggedized lenses and optical systems produced can withstand the launch vibration and shock profile

provided by the customer, Resolve Optics has invested in in-house testing equipment.

To learn more about ruggedized lenses for space projects please watch the video on www.resolveoptics.com/videos/ or contact Resolve Optics Ltd. on +44-1494-777100 / sales@resolveoptics.com for further information.

Ruggedized lenses for spaceborne projects

Ruggedized lenses online video 16|

Choose a Guardtech Decontamination package to help your facility shine

Cleanroom construction specialists providing comprehensive bespoke Decon offering as part of their Cleanroom Service Plan

THE GUARDTECH GROUP are offering businesses peace of mind by providing a comprehensive package of decontamination services – either as part of a Cleanroom Service Plan or scheduled separately.

The Decon Team work to GMP standards and are specialists in restoring control to critical environments, offering bespoke cleaning programmes and comprehensive multistage cleaning as and when required.

Guardtech’s well-trained and experienced operatives follow client SOPs and use specific validated chemicals and equipment when required, with the two most senior leaders of the team boasting 30 years’ experience in decontamination.

From builders’ cleans and pre-validation cleans to biocidal/ sporicidal cleans, the Guardtech Group Decon Team are certified to work at height (IPAF PAL card holders).

They can conduct full microbiological/bioburden testing with TSA & SDA plates and pre-clean and post-clean contact plate testing, as well as cleanliness verification tests with full reporting.

But that’s not all – because for ultimate peace of mind, Guardtech provide a hydrogen peroxide fogging service, either as part of their Cleanroom Service Plan or a Decononly Programme.

The Decon Team utilise EndoSan SHP dry misting technology – proven to achieve greater than log 5 reduction (99.999%) in bacteria and at least a log 3 (99.9%) reduction in virus of the coronavirus family.

For more information visit www.guardtech.com.

|17 June 2023 ENGINEERING PDATE

Image Copyright

Guardtech

HVAC systems based on SIMCom IoT modules

Improved performance and speed of operation

• SIM7600X modules

• 7672E modules

• Real-time monitoring of environmental parameters

It feels quite natural that public utility building interiors are warm in wintertime. It results from the fact that shopping centres, schools, office buildings, museums or offices are heated and operated by HVAC systems. This mysterious acronym stands for – (), () and (), ventilation and air conditioning. In Polish, also the “COWiG” abbreviation has been derived from Polish words “ciepłownictwo, ogrzewanie, wentylacja i gazownictwo”, meaning “space heating, heating, ventilation and gas supply”. Whichever term we use, the meaning is the same, as it covers the technologies used to create and maintain comfortable conditions for work and rest in buildings.

In other words, these systems are responsible for monitoring and adjusting environmental conditions in such a manner that each room always has the right temperature and humidity, and the indoor air is always fresh. Moreover, it must be noted that maintaining the right conditions also exerts an optimum impact on the physical condition of a building itself. System capabilities include lowering the humidity and temperature in the building when its occupants are away for longer periods of time. Buildings designed in line with the HVAC-related requirements can be cooled or heated both in winter- and summertime, and the supply and filtration of clean air pumped into interiors is also ensured. Moreover, it is worth remembering that correct HVAC management results in optimising the electricity consumption costs.

HVAC system actuators include air handling units, heaters, fans, heat pumps or infrared heaters. They are managed by suitable controllers using data collected from environmental condition sensors located on site. While

• Automatic control of HVAC systems

• Early prevention of malfunctions –ensured by SIMCom solutions

• Energy-efficiency in HVAC systems

designing an HVAC system for a small building, a wired connection of all the components can be considered, but as the system expands, such a solution becomes quite problematic. In such cases, it is worth turning to such options as wireless communication or IoT solutions. One of the communication solutions that can be applied to connect HVAC system components is the LTE radio transmission that is well-known by users of all devices connecting to the Internet. Ready-made LTE modules manufactured by SIMCom facilitate adaptation of HVAC equipment to state-of-the-art solutions. They not only ensure reliable connectivity and data transmission support, but also facilitate a smart transformation of a legacy HVAC system.

SIM7600X modules

SIM7600X is a family of modules that support wireless LTE data transmission. These systems are based on Qualcomm chips and designed for global market applications, so they support numerous wireless communication technologies, at 10 Mbps (downlink) and 5 Mbps (uplink).

The overview of their key features:

• compact design facilitating implementation in existing solutions;

• wide selection of external interfaces (ADC, GPIO, I2C, PCM, SDIO, SIM, UART, USB 2.0);

• software adjusted to IoT solutions;

• availability of regional variants (EU/Japan/North America/Latin America/Australia and Oceania).

18| June 2023 ENGINEERING PDATE

LTE modules – perfect solutions for IoT applications

7672E modules

The A7672E series is another type of modules provided by SIMCom. These are slightly more expanded LTE devices, whose maximum downlink transmission rate is up to 10 Mbps (up to 5 Mbps downlink). These modules are also quite compact, so adapting them to an individual project should not be a problem for engineers. Other characteristic features include:

• support for LTE Cat.1 with 2G fallback and LTE Cat.1/ Cat.1 Bis Protocol;

• embedded GNSS/BT5.0 function (available only in selected models);

• compatibility with SIM7000/SIM7070/SIM800F;

• Dual SIM support.

Real-time monitoring of environmental parameters

The SIMCom LTE modules can operate within the existing LTE networks and ensure reliable wireless communication performance. Sensors with SIMCom LTE modules support real-time monitoring of the HVAC equipment operation. This data can be uploaded to a cloud-based computing platform and displayed in the form of graphs and analyticsbased indicators, providing building managers with a more intuitive way to understand the current system status. Data can also be accessed by residents or office building staff using a mobile phone, etc.

Automatic control for HVAC systems

Availability of a large number of external interfaces makes SIMCom modules compatible with various types

of sensors supported by HVAC systems to automatically adjust temperature, humidity, air quality and other settings.

For example, a temperature sensor equipped with such a module can transmit the current room temperature values to a database in which records are analysed in real time. In combination with the analysis of historical operating data from the air handling unit, external weather data, building characteristics and other references, it can ensure precise and automatic room temperature adjustments.

An air quality sensor can also upload data to a database via an LTE network. Moreover, the system can automatically adjust the volume of fresh air supplied by comparing it with a setpoint value, so that the indoor air quality is always maintained at the right level. The fact that a SIMCom LTE provides data instantaneously enables HVAC system actuators to respond to current users’ needs almost instantly.

More and more common PV farms can also be equipped with SIMCom modules facilitating wireless communication. Systems operating within the entire installation can be managed and monitored easily using such a module. Another advantage of wireless LTE modules is their reach. PV farms are often located at large distances from other structures, which makes managing them troublesome, but LTE radio networks offer perfect solutions to such problems.

Early prevention of malfunctions – ensured by SIMCom solutions

Apart from providing environmental data, SIMCom modules can also supply information on the HVAC system actuator operating status. By analysing such data, the system can predict malfunctions, and thus avoid costly downtime and ensure long and stable operation of the HVAC system.

Energy-efficiency in HVAC systems

Continuous operation of an extensive installation results in the significant energy consumption. It is therefore worth looking for ways to increase energy-efficiency, for example by implementing a smart monitoring system. By collecting environmental, historical and user preference data, the management system can proactively adjust the equipment operation to maximally reduce electricity consumption.

|19 June 2023 ENGINEERING PDATE SIM7600E-H

C.K TOOLS JOINS PUSH FOR FIRE SAFETY WITH LAUNCH OF LS0H CABLE STRIPPERS

C.K Tools, the trusted choice for trade professionals, has launched a range of cable strippers designed to tackle low smoke zero hydrogen (LS0H) cable. Use of LS0H cable is increasing as specifiers bid to improve fire safety, but stripping this much tougher material is a challenge.

Now widespread in Ireland and the USA, use of LS0H cable is on the rise in the UK. While PVC cable jacketing may be fire resistant, it can generate around 50 per cent its weight in smoke when exposed to high heat or flames. This thick, acrid smoke is highly toxic, corrosive, and can damage electrical equipment. Toxic smoke inhalation causes more fire-related deaths than fires themselves. As such, many specifiers are opting to replace PVC or other cable jacketing with LS0H, and –with the legacy of the Grenfell Tower tragedy looming large – it is expected that regulations to this effect will soon be introduced.

Faced with LS0H, many electricians have reported challenges in stripping the cable, as standard cable strippers fail to meet the strength of the thermoplastic material. C.K Tools’ new LS0H cable stripper, however, has been designed specifically for the task.

Compatible with round, flat, and LS0H cabling, C.K Tools’ latest strippers make light work of all cable types thanks to their two titanium nitrade coated blades and four cable brackets. The range includes a 10mm flat and LS0H bracket, a 6mm flat and LS0H bracket, a 2.5mm flat and LS0H bracket, and an 8-28mm round bracket.

The stripper itself boasts a self-locking switch, automatic blade protection, and keyless blade adjustment, alongside the titanium nitrade coated blades. The range is available as a set with the stripper included, and LS0H brackets can also be purchased as a set of three.

Brinley Buckley Roberts, brand manager at C.K Tools, says: “There is a very real problem in the industry of electricians finding themselves ill equipped to tackle LS0H cable. The rising prevalence of LS0H is necessary and will undoubtedly save lives. We must prepare for it to become the norm. Our new cable stripper has been precision engineered to take on the challenge. Users can also expect the quality, durability, and ease of use that we pride ourselves on at C.K Tools – always ready to meet the most demanding needs of trade professionals.”

www.ck-tools.com

June 2023 20| ENGINEERING PDATE

Lenze is taking drive performance to the next level with the i750 servo inverter

High-performance drive solutions are crucial for efficient and automated production processes. In order to optimally equip tomorrow's machines for demanding motion tasks, Lenze is expanding its portfolio with a new servo inverter: The i750 cabinet for motion control applications, in combination with modern Lenze controller, solves almost all automation tasks for dynamic multi-axis applications.

Thanks to more than 75 years of experience in drive technology, Lenze offers a powerful solution for motion control applications with its i750 cabinet multi-axis servo inverter.

Björn Maltzahn, Motion Control Product Manager at Lenze, explains: "Our new servo inverter represents a consistent evolutionary development of our portfolio. The i750 masters complex applications and offers mechanical engineers new design scope for future-proof solutions."

Automation at the highest level

The servo inverter boasts outstanding precision and dynamics and allows operators to increase the cycle rates of their machines by up to 20 percent. In combination with

a Lenze controller, the auto-tuning function also makes commissioning much easier and improves machine efficiency. The i750 product range consists of power supply modules and single and double axes, which are operated in a DC network. Key features are a narrow width and extensive integrated safety technology. The units can be used universally in the power range from 1.1 to 15 kilowatts for single axes and from 1.1 to 7.5 kilowatts for double axes. Between 22 and 110 kilowatts, the i950 cabinet servo inverter acts as a power extension.

Unbeatable package

Björn Maltzahn reports: "The i750 offers all the advantages of an open EtherCAT CiA402 interface and is

used in centrally controlled system architectures. Its full potential becomes apparent in conjunction with the Lenze controls, making it an indispensable element in sophisticated automation systems. Users benefit from both maximum accuracy and higher throughput."

One-cable technology throughout

The i750 servo inverter series supports the operation of motors spanning the entire power range using one-cable technology (OCT). Björn Maltzahn: “One-cable technology saves users more than half the installation effort as well as valuable space in their control cabinets.”

Safe choice for the future

The servo inverter’s integrated safety functions cover a broad range of safety-related machine applications. As a result, the device meets safety-related requirements up to safety integrity level 3 (SIL 3) and performance level e (PL e). Even more extensive options to safeguard machine functions are provided by extended safety functions such as safe-limited speed (SLS), safe direction (SDI), and safe-limited position (SLP). www.Lenze.com

|21 June 2023 ENGINEERING PDATE

The electric car giving driving lessons to children under 10

A real electric car in miniature is giving children as young as four the opportunity to start their driving career early. With lessons from £20, the aim is to set children on course for excellent road safety and driving skills before these young drivers pass their test for real. Young Driver Motor Cars is providing this realistic driving experience using maxon motors.

According to the Department for Transport, young drivers, including those between 17 and 24 years old, are more likely to be involved in an accident compared to other age groups. Young drivers also have relatively higher injury rates in road collisions. The need to make driving a safer experience for the young was the motivator for Ian Mulingani in his leadership of Young Driver.

The Young Driver scheme provides driving lessons to children throughout the UK in safe areas, off the public highway. Through government-approved instructors, the aim is to give young learners a head start and enable them to become safer drivers. Originally, the scheme provided lessons to children aged between 10 and 17, but following demand from parents, 10 years old wasn’t young enough.

Firefly Mk I

“Parents would bring along younger brothers and sisters who wanted to try our driving lessons, but children

of this age were too small to drive the standard, road-going cars we use for 10- to 17-year-olds,” says Ian. “I tasked our team to buy some small electric cars, but they couldn’t find anything suitable. They were either unrealistic toys, not durable enough for our needs, or collectors’ items costing £30,000-plus. I realised we needed to make our own.”

In 2016, Ian worked with a team including external partners to develop an initial model. The first version of the Firefly, with 12 cars produced, delivered around 12,000 lessons to drivers as young as four.

“After four years using the cars, we’d replaced the batteries a few times, and the motors were still running perfectly.

22|

We were using motors from Parvalux by maxon, which came recommended from our engineering partner at the time,” says Ian. “The car bodies were however in need of attention - as you would expect at the hands of such youngsters behind the wheel – so instead of refurbishing the cars, we took the opportunity to develop a new, improved model.”

Thanks to Ian’s automotive background, he was able to call in engineering expertise, including fellow former Jaguar-Land Rover colleague, Dr Ian Pogson, who began working on the design of the electric powertrain for the Firefly Sport.

“This time, we ran the car development project just like we had done at JLR,” says Dr. Pogson.

Firefly Sport

The new car includes an upgraded aluminium chassis with independent suspension designed by former Aston Martin prototype guru, Steve Rawson, as well as rack and pinion steering. The body design was even derived from market research among the car’s user group: a survey among drivers under 10 years old.

To power the Firefly Sport, the Young Driver team immediately returned to Parvalux motors on the basis that they had already proved themselves.

“The motors provided the speed and power we needed, and they just kept going with no maintenance required, so we knew they would give us the right performance,” says Dr. Pogson.

Just like modern road going electric sports cars, the Firefly Sport is powered by twin electric motors. Rear mounted right angle gear motors, one per rear wheel, are installed on a pair of swing arms with a spring and damper. Maxon specified the Parvalux PMDC right angle motor for its high starting torque and smooth, controlled speed delivery. The motors are combined with a Parvalux GB9 right angle, worm wheel gearbox to optimise torque control.

Running time for the Firefly Sport is also key. This means the motors needed to provide high efficiency,

while offering sufficient torque in a lightweight package to minimise overall power requirements.

“Removing and replacing the battery during a Young Driver session isn’t a practical solution,” says Ian, where the Young Driver team provides 15-minute lessons from morning to late afternoon. “Instead, we needed a lightweight, efficient motor, combined with the right battery technology, that can run all day.”

The Firefly Sport, weighing just under 200kg, can operate for up to eight hours on a single charge, driving at speeds around 5mph. The car can travel significantly faster in return for a shorter battery life, but the limited speed is optimal for the young driver experience. After use, the specialist high-cell batteries are recharged using a solar power system, minimising running costs, and ensuring a zero-emissions operation.

Practical engineering support from maxon also helped optimise safety, with advice on how to lock the motor to prevent the car moving when the accelerator pedal is disengaged, like when the car’s stationary on a slope, or if the young driver has brought the car to a stop.

“We had already adjusted the motor on the workbench without success, so maxon came to see the car and showed us that after the turnbuckle adjustment, the motor required a load and resistance for the brake to function,” says Dr. Pogson. “Just 15 minutes

with maxon’s engineer, hands-on with the car, was all it took to resolve our challenge.”

Increasing young driver safety

With six cars completed and a further six in progress, Young Driver Motor Cars is looking to expand production. 150 enquiries have already been received from around the world, and the Firefly Sport is set to retail for around £11,000. Young Driver’s main intention for the new car though is to expand the potential reach of driving lessons for the young, which now offers driving lessons from four years old and up.

“The national average rate for young drivers suffering an accident in the first six months after passing their driving test is 20%, but for Young Driver pupils, it’s just 3.8%, a safety improvement of over 80%” says Ian.

“Young Driver lessons normalise driving as an experience,” says Ian. “If you’ve been driving since you were younger than 10, there isn’t the same pressure to drive beyond your capabilities when you eventually pass your test. Secondly, the younger you are when you start to learn, the more opportunity your neural networks have to build, improving your driving capabilities and safety. If you’re four years old today, you'll probably only ever drive an electric car, so Firefly Sport becomes a realistic starting point for your safe driving future.”

www.maxongroup.co.uk

|23 June 2023 ENGINEERING PDATE

Series

HIGH ACCURACY IS THE OPTION

Pressure Ranges 0…0,3 to 0…1000 bar

Accuracy ±0,05 %FS

Total Error Band ±0,1 %FS @ -10…80 °C

Interfaces RS485, 4…20 mA, 0…10 V

Operational Temperature Range -40…120 °C

keller-druck.com

June 2023 24| ENGINEERING PDATE

35X

Fluid Carr ying Flexibility Swivel Joints Bingswood Trading Estate Whaley Bridge | High Peak | SK23 7LY | UK Articulated Pipework Torsion In Hoses Rotating Cylinders Swivel joints allow pipework to pressure 1/4” to 40” and beyond. Vacuum to over 20,000psi Stock and bespoke production. Unique bearing/seal design for longer life. ISO 9001 CE marked where applicable. Tel: +44(0)1663 735003 E-mail: |25 June 2023 ENGINEERING PDATE UNCOMMON EXCELLENCE DESIGN CUSTOMER SERVICE INNOVATION MANUFACTURING QUALITY TECHNICAL EXPERTISE UNCOMMON EXCELLENCE DESIGN • Hoses and hose assemblies • Hose & pipe fittings • No-spill couplings • Safety breakaway fittings • Blow-Out prevention couplings • Hydraulic Fracturing: Low Pressure Systems • Loading arms • Liquid level sensing • Zero emission valves Fluid transfer products for upstream, downstream and refining • Global inventory and locations • Sales and technical support worldwide • In-house engineering & design • ISO 9001 accredited • Pressure Equipment Directive Products: Dixon Petrochemical Products

The essential tool for Zone 0 Explosive Atmospheres cygnus-instruments.com • sales@cygnus-instruments.com • Certified to ATEX, IECEx, UKEX for Zone 0 and NRTL for Class 1, Division 1 • 3 measuring modes for corrosion, various materials and through-coat measurements

Manual Measurement Mode allows gates and gain to be configured to suit your application

Live A-Scans and B-scan for visual verification

4 quick function keys for easy control

Comprehensive data logging for easy reporting The Cygnus 1 Ex Ultrasonic Thickness Gauge is a rugged, intrinsically safe instrument designed for taking thickness measurements in Zone 0 explosive atmospheres. LNG/LPG TANKERS STORAGE

OFFSHORE

MINES OIL AND GAS REFINERIES DISCOUNT CODE EU2023

•

•

•

•

TANKS

PLATFORMS

The networking exhibition for the lifting equipment industry

Sponsors and Partners: Hosted by:

u Live Demos u Innovation

Discussion u Training

u

liftex.org #liftex2023

Packed show floor of lifting equipment and services

21-22 November Exhibition Centre Liverpool

BOOK NOW

FREE TO ATTEND FOR USERS AND BUYERS OF LIFTING EQUIPMENT ACROSS MULTIPLE MARKETS

What’s new?

• 80% of stand space already sold

• Powell Electronics confirms headline sponsorship alongside Wurth Elektronik and Solid State Supplies

• Dassault Systemes returns as gold lounge sponsor and sponsor for The Engineer conference and Eureka conference

• Mouser Electronics confirm lanyard sponsorship

Design Show!

Previous exhibitor, Adam Miller, Field Sales Engineer from Ineltek commented on last year’s show:

“The resurgent Engineering Design Show exceeded expectations. Ineltek’s stand had a steady stream of relevant visitors from a variety of technology businesses. The two days flew by; we never reached the point where we had to kill time visiting other stands. EDS is back with a bang!”

The Engineering Design Show (EDS) returns to The Coventry Building Society Arena on the 11th – 12th of October 2023. This two day exhibition has been curated specifically for design engineers and will bring together over 200 suppliers, thousands of products and all the latest industry innovations.

The exhibition is set to be jam-packed with hundreds of stands already booked. Exhibitors include Moons Industries, Technosoft, Telsonic, Smallfry, McLennan, Thermal Vision Research, Etal, Quickparts, Hoover, The Robot Studio and Reliance Precision and many more!

Alongside the exhibition, visitors can attend 30+ hours of free conference sessions and workshops, bringing together the biggest names in the industry. There will also be ample space for one-to-one meetings and time to network, with the dedicated gold lounge, sponsored by Dassault Systemes, a central café and a drinks reception held at the end of the first day.

EDS has everything to support UK design engineers in 2023. Register your interest here to be the first to find out when registration opens and to keep abreast of all the latest show news: https://www.engineeringdesignshow.co.uk/register-interest

Interested in exhibiting?

Exhibiting at EDS is a fantastic way to maximise your organisation’s exposure to the UK’s design engineering community. For more information, visit engineeringdesignshow.co.uk and find out how we can tailor your package to meet your exact requirements.

30| June 2023 ENGINEERING PDATE

Hundreds of exhibitors are already confirmed for this year’s Engineering

Interested in exhibiting? Get in touch with simon.bonell@markallengroup.com HEADLINE SPONSORS THE UK’S BIGGEST EVENT DEDICATED ENTIRELY TO ENGINEERING, ELECTRONICS AND EMBEDDED DESIGN 11-12 October 2023 Coventry Building Society Arena Join thousands of design engineers this October! Source the latest products, services and innovations available to the sector. Register your interest today. www.engineeringdesignshow.co.uk @EngDesignShow #EngDesignShow Interested in Exhibiting? Visit the website to find out more.

Fluregiene 200™ provides protection for hygiene conscious parts and surfaces • Excellent corrosion resistance • Low friction anti-fouling and anti-stick properties • Durable and easy to clean/wipe down • Permanently applied to metals, alloys and plastics • Built-in antimicrobial technology actively reduces microbes on the surface of the coating. • Reduces fungal growth and surfaces stay fresh longer Low friction PTFE based coating containing BioCote® antimicrobial technology Fluregiene 200™ Protecting your surfaces for longer. For more information about Fluregiene 200™ call us now on +44 01386 425755 or email info@cwst.co.uk Easy cleaning of hygiene conscious parts Reduces microbial growth Permanent coating protection