020 805 09659 | www.engineering-update.co.uk

The importance of corrosion protection for electric vehicles

[click here]

High stability beam collimators for military optics testing [click here]

From parts to perfection

Automation needed to handle the world’s smallest devices.

[click here]

APRIL 2024

EngineeringUpdate ENGINEERING - AUTOMATION - MANUFACTURING

London Packaging Week Innovation Awards open for entries [click here]

Engineering Update 2

APRIL 2024

Engineering Update 3 4 Contents ODU Connectors - The increasing importance of online product searches in a networked world USB-C connectors and SD card slots by GCT High stability beam collimators for military optics testing 6 8 The Fusion of Robotics, AI, and AR/VR: A 2024 Revolution in Manufacturing. 20

To feature in the next edition of Engineering Update. Call 020 805 09659 or email hello@engineering-update.co.uk Innovation here]

USB-C connectors and

High product quality and broad capabilities of the standard.

Since USB-C connectors became an official standard applicable in the European Union, the demand for various variants thereof has been growing steadily. Global Connector Technology (GCT) is one of the leading suppliers specialising in manufacturing USB-C ports and plugs.

This article contains an overview of the product range offered by GCT (Global Connector Technology), a company specialising in connectors installed in compact mobile device enclosures, PC peripherals, IoT circuits (Internet of Things) and diverse types of modules, mostly for industrial and remote control applications (e.g. alarm systems). The manufacturer offers a broad range of such products as: USB-C connectors, storage media slots or SIM card slots. They are not only characterised by their compatibility with popular standards, but also their excellent value for money.

This article covers the following issues:

• Key advantages of the USB-C standard

• Are USB-C connectors a European standard?

• Characteristics and versions of connectors offered by GCT

• Diverse assortment of memory and telecommunication card slots

USB-C connectors

Firstly, it must be noticed that the USB-C standard refers to physical connectors and does not guarantee full compatibility with specifications such as USB 3.2, the transmission speed specified in the characteristics of this interface, its full functionality, etc. The GCT products are developed primarily to provide durable and compact power supply/charging connections that comply with the latest regulations. Whilst all USB Type C connectors support both power supply / charging, USB3.2 data transmission is only available on 24 posn devices, whilst the USB 2.0 communication std can be realized on 16 posn parts. When only Charging (ie

no data transmission) is required, the GCT 6 posn USB Type C product range offers the most cost-effective solution.

Capabilities offered by the standard

USB4800-03-A 16-pin versions

The USB-C connector format has swiftly become popular, which has recently resulted in the fact that it is specified as a standard connector in the European Union. All mobile devices released for sale in the Member States must be equipped with this connector format. It ensures not only consumer’s comfort, but also reduction in electro waste generation, as buying a new phone or other device does not mean that the previous charger will turn out to be incompatible.

USB4520-03-1-A

Middle board mount type

USB4145-03-0230-C

Vertical installation

The GCT connectors implemented in projects come with all advantages offered by this format. The first such advantage is its compact size. Reversibility is another one, as the plug can be connected in two positions, after reversing it by 180°. The third key advantage is the possibility to “maximise” the power supply delivery between devices (up to 240W ( 5A @48 V DC) on 24 and 16-pin versions maximizing USB Power Delivery capabilities).

Engineering Update 4

and SD card slots by GCT

Global Connector Technology products

Note also that GCT ports come in several installation variants, which ensures space savings inside device enclosures (or on a PCB). The most typical connector format is designed for SMT assembly, although usually also incorporating THT shell stakes to improve the mounting stability of the entire component. Moreover, the product range also includes models with both surface-mounted leads and shell stakes (Fully SMT). The third variant facilitates installing the components in such a manner that the connector symmetry axis overlaps with the PCB cross-section, known as a Mid-mount configuration. The connector is placed in a laminate slot to obtain an ultra-low circuit profile being a perfect solution for the design of smartphones, tablets, games consoles, smart watches and other hardware in which, literally, every cubic millimetre of internal space counts. GCT USB Type C products are also available in vertical versions (in relation to a PCB), used for example, in docking stations, certain charger types, etc.

Note also that USB-C connectors offered by Global Connector Technology are characterised with high reliability, as the manufacturer has fully tested their mechanical life at 10,000 or even 20,000 mating cycles (2x USB Industry standard).

SD and SIM card slots

Another notable group in the GCT product range includes slots for SD and SIM cards, i.e. storage media and cards providing access to wireless telecommunication networks. In this range, the manufacturer provides a broad and diverse assortment of surface-mounted components. They come with gold-plated contacts (resistant to corrosion, in particular typical atmospheric humidity) and can operate within an extensive temperature range, even from -40°C to 85°C (depending on the model).

The GCT assortment of slots includes both models with a self-locking mechanism, e.g. push-pull or push-push, for easy card insertion into an enclosure slot, and models with a tilted cover, mainly used for embedding cards in elements where they are rarely replaced (e.g. industrial modules or alarm system circuits). The table above provides an overview of formats available in the manufacturer’s portfolio, i.e. slots compatible with microSD and Mini/Micro/Nano SIM cards.

The constant demand on communication and memory card slots is related to the development of devices that aggregate and store significant amounts of data. They include not only consumer products, such as : smartphones, video recorders or cameras, but also professional hardware (meters, counters). Communication over mobile networks has become increasingly common in the IoT sector (Internet of Things), which includes not only household gadgets, but also remotely-controlled environmental condition sensors (for example, used in agriculture, infrastructure or meteorology), street light controllers, vehicle fleet monitors, etc. Products offered by Global Connector Technology contribute to extending the life cycle of such equipment, and at the same time ensure cost optimisation in terms of manufacturing.

MEM2061-01-188-00A microSD

SIM6050-8-0-30-00A Mini SIM

SIM7100-6-1-15-00A Micro SIM

SIM8055-6-1-14-00A Nano SIM

www.tme.eu

Engineering Update 5

ODU Connectors

The increasing importance of online product searches in a networked world - ODU Product Finder as an innovative solution

In recent years, the digital transformation has not only affected and changed the B2C market, but also the B2B sector. One of the most notable changes is the increasing importance of online product search engines. Companies are increasingly looking for efficient and timesaving methods to find business partners and suppliers and to evaluate products and services.

In this context, online product search is rapidly gaining relevance in the B2B sector, as it not only speeds up searches but also facilitates access to global markets. As a leading international manufacturer of connectors, ODU recognizes the need to support traditional product search methods while also continuously investing in the further development of the ODU Product Finder, ODU’s online search engine.

Interview with Dominic Krieg, Digital Product Management Expert at ODU

Dominic, what needs does the ODU Product Finder fulfil for your users?

Our Online Product Finder enables users to find exactly the right product in just a few clicks. The processing of the wide range of variants using filter criteria makes the search considerably easier compared to conventional catalogues. Our users can not only call up concise product information, but

also configure product variants themselves. The integration of 3D data for download rounds off the offering. The result is a comprehensive, efficient and user-friendly product search process.

How has the use of online product portals developed, and what trends or changes have you observed?

The use of online product portals has increased significantly over time. Digital search options have been further developed so that they not only enable efficient product searches, but also increasingly focus on personalized user experiences and comprehensive data accessibility. The ongoing trend shows an increased integration of design data, a broader product range and an increased focus on user-friendly, intuitive search functions to meet the growing demands of users.

What future developments are you planning for your ODU Product Finder?

In order to further enhance the users’ experience, we are planning to continuously expand the availability of product information, extend the cable assembly portfolio and constantly develop the guided search to improve intuitive use.

Engineering Update 6

Despite different entry options, the user should be able to find the right product immediately. In this way, we want to maximise user-friendliness and guarantee outstanding product and service quality.

What type of users particularly benefit from your ODU Product Finder?

Our ODU Product Finder is aimed at purchasers, design engineers and product managers, among others. The variety of functions offered, such as 3D data for designers and data sheets for purchasers and product managers, enables needs-orientated use.

Access is provided without login and the user is free to decide what contact information to disclose to us.

How do you integrate user feedback into the further development of your ODU Product Finder, and what role does customer feedback play in improving your digital offering?

Our Product Finder is a dynamic tool that continuously takes into account both internal and external feedback. Customer feedback plays a central role in identifying areas for improvement and we actively encourage users to try out the tool and share their feedback with us.

So, we would be delighted if you would try our Product Finder for yourself at: odu-connectors.com/find-your-product/ You can also find a detailed explanation at: vimeo.com/867818453

Engineering Update 7

High stability beam collimators for military optics testing

Optical Surfaces Ltd has supplied two reflective beam collimators to a leading European supplier of high precision optics to military and defence contractors.

Reflective beam collimators are mirror assemblies that take divergent or convergent incoming light and produce parallel output. They can be used to replicate a target at infinity without parallax. Consequently, reflective beam collimators are the device of choice for performing Modulation Transfer Function (MTF) measurements over extended wavelength ranges.

Dr Aris Kouris, Sales Director of Optical Surfaces Ltd said “MTF is a technique, trusted by optical designers, for objectively evaluating the image-forming capability of military optical systems. We were chosen as a partner for this project because of our track record in supplying affordable, high performance beam collimators tailored to enable precise MTF testing of military optical systems”.

He added “The high stability and performance of our reflective beam collimators is achieved using a zero expansion off-axis parabolic mirror, manufactured to better than lambda/10 p-v surface accuracy. The allreflecting design of our beam collimators is achromatic and with aluminium / magnesium fluoride coatings can operate from the UV to the infrared without adjustment. The optics

within each beam collimator are secured using stress-free mounts and come pre-aligned for optimum performance. The off-axis design of our beam collimators produces no central obscuration thereby ensuring highly efficient transmission is obtained”.

Benefiting from a lightweight design and new assembly technique – Optical Surfaces beam collimators uniquely combine high stability, high performance, and short delivery time all at a market competitive price.

For further information on reflective beam collimators tailored to your application please visit optisurf.com/reflective-collimators/ or contact Optical Surfaces Ltd. on +44-208-668-6126 / sales@optisurf.com.

The company’s ISO 9001-2015 approved manufacturing workshops and test facilities are deep underground in a series of tunnels excavated in solid chalk. This provides an environment where temperature is naturally thermally stable, and vibration is extremely low. With such stable conditions testing of all beam collimators becomes quantifiable and dependable. In addition to these natural advantages, Optical Surfaces Ltd. has invested in an extensive range of test equipment and uses trusted methods to ensure accurate and reliable testing of surface accuracy, quality, and slope errors. optisurf.com/reflective-collimators

Engineering Update 8

Titan Enterprises Analyses Solutions for Low Flow Liquid Measurement

The measurement of low flow is becoming widely used in many industries. However, the smaller the flow, the trickier it is to control and measure, and finding a suitable flow measuring technology at reasonable cost can prove challenging for both users and flow sensor manufacturers.

There is no set definition for ‘low flow’ in terms of measurement limits for fluidics handling. However, low-flow applications encounter amplified flow stability and performance issues not seen in larger flows. The minimal liquid volume being measured in low flows renders them highly sensitive, such that even the slightest disruptions in process or ambient conditions can exert a substantial impact on flow stability.

Within the markets Titan Enterprises operates in, we consider low flow rates as those below 50 ml/min, with many customers seeking flow rates of between 2 and 20 ml/min.

Neil Hannay, Titan’s Senior R&D Engineer observes: “We are certainly seeing an increase in demand for low flow measurement technologies driven by various industries moving towards transporting heavily concentrated liquids, which are then diluted at the point of use. This translates into huge savings on transport and storage costs and also has a positive environmental impact.”

Whether cleaning fluid additives, syrups and flavourings for beer or soda, chemical additives for oil and fuel, paint pigments or administering drugs, low flow flowmeters are required to dose these concentrated fluids at the end process, dispensing the precise amount of liquid to the correct dilution.

As mentioned, measuring low flow is a challenging application to satisfy. The amount of energy available in low liquid flow is unlikely to be sufficient to drive most mechanical flowmeters to give linear results. By comparison, electronic flow meters can be limited by sensitivity, zero drift and slow response times.

As flowmeters can be the most limiting component of a low flow fluidic system, it is essential to choose the most suitable highprecision flow sensor for your application.

“We know there is a strong market for low flow meters and we are currently working with two international OEMs to develop a solution for measuring ultra-low flows using our oval gear technology and miniaturised gears,” says Neil.

Engineering Update 10

Titan Enterprises’ website for further information on low flow measurement or to discuss specific technical applications,

contact Titan Enterprises on +44 (0)1935

or email sales@flowmeters.co.uk.

Visit

please

812790

Here we analyse 5 types of flow meter - Ultrasonic, Turbine, Oval Gear, Thermal and Coriolis and their suitability for low flow measurement:

Ultrasonic

• Ultrasonic flowmeters measure the velocity of flow. Titan’s in-line Atrato© models, using patented time of flight technology, are capable of measuring flows down to 2ml/min. Lower flow rates equate to smaller signals to determine flow rate and as such, this lower signal strength can affect the flowmeter’s capability to produce repeatable measurement results.

• Design challenge: Straight-forward engineering vs complex electronics

• Advantages: High accuracy; not fluid specific; high signal to noise ratio; no pressure drop requirements; suitable for both turbulent and laminar liquid flow

• Disadvantages: Susceptible to process vibrations/pulsations/noise; sensitive to gas entrainment

Turbine

Oval Gear

• The energy required to spin the rotor of a turbine flowmeter becomes swamped by the drag from the system at low flow rates. As flow rate reduces and transitions from turbulent to laminar flow, the linearity changes and the measurements become less accurate. Pelton wheel turbines that use low friction, precision bearings can mitigate this effect to some degree and with careful design, are capable of flows down to 1-2ml/min. They are capable of fast response times and operate across wide flow and operating temperature ranges.

• Design challenge: Straight-forward electronics vs complex precision engineering

• Advantages: Low cost; can be calibrated in-situ; good accuracy and repeatability with rapid response times

• Disadvantages: Susceptible to changes in fluid properties; requires sufficient pressure to move liquid through the pipeline at a rate that causes the turbine blades to spin

• Positive displacement flow meters, such as oval gear meters, are particularly effective for measuring low flow viscous fluids, although the resolution can be quite low. To obtain good resolution, the oval gear meters need to be small in low flow applications. Installing an oval gear meter in a horizontal position will reduce rotational friction and improve low-flow measurements. The lower the flow, the smaller the gear size, which are manufactured to tight tolerances with small internal clearances to minimise any fluid leakage around the gears

• Design challenge: Straight-forward electronics vs complex precision engineering

• Advantages: Ideal for viscous liquids, precision chemical dosing; good reliability

• Disadvantages: Not suitable for low flow aqueous solutions as the slippage past the moving element is greater than the volume being measured. Trapped air can prevent small gears from rotating – ensure all gas is purged on initial startup. Low resolution

Thermal

• Thermal flow sensors, primarily used for monitoring gas flow, operate on the principle of monitoring thermal transfer using a reference temperature, a heat injection and a detector. The basic approach is that heat is added to the flowing stream and a temperature imbalance being used to obtain a flow rate. They are fluid-specific as the technology relies on the liquid’s thermal properties and are generally calibrated for the specific fluid properties.

• Design challenge: Relatively simple engineering vs complex electronics

• Advantages: Highly sensitive and able to measure flow rates down to nanolitres per minute; suitable for low pressure drop applications; not so reliant on the dynamics of the fluid to make a measurement

• Disadvantages: Fluid-specific. Thermal low-flow liquid flowmeters are non-linear over their temperature range and so require some correction during the process. Not suitable for low boiling point liquids or liquid mixtures with changing composition

Coriolis

• Thermal flow sensors, primarily used for monitoring gas flow, operate on the principle of monitoring thermal transfer using a reference temperature, a heat injection and a detector. The basic approach is that heat is added to the flowing stream and a temperature imbalance being used to obtain a flow rate. They are fluid-specific as the technology relies on the liquid’s thermal properties and are generally calibrated for the specific fluid properties.

• Design challenge: Relatively simple engineering vs complex electronics

• Advantages: Highly sensitive and able to measure flow rates down to nanolitres per minute; suitable for low pressure drop applications; not so reliant on the dynamics of the fluid to make a measurement

• Disadvantages: Fluid-specific. Thermal low-flow liquid flowmeters are non-linear over their temperature range and so require some correction during the process. Not suitable for low boiling point liquids or liquid mixtures with changing composition

Engineering Update 11

The importance of corrosion protection for electric vehicles

Corrosion protection is as important for electronic vehicles (EVs) as it is in traditional petrol/gasoline powered vehicles. However, there are some unique factors to consider when it comes to avoiding corrosion problems in electric vehicles:

Battery Enclosure and Connections:

EVs have large, heavy battery packs that are typically enclosed in a protective housing. This enclosure and its connections can be particularly susceptible to corrosion, especially in regions with high humidity or exposure to road salt. Corrosion in the battery enclosure or on electrical connections can affect the performance and safety of the vehicle.

Charging Infrastructure:

Charging equipment, especially in public charging stations, can be exposed to the elements. The connectors, plugs, and wiring can corrode over time.

This can lead to issues with charging reliability and safety concerns.

Cooling Systems:

Many EVs use liquid cooling systems to manage the temperature of the battery. The components in these systems, such as radiators and coolant lines, are vulnerable to corrosion. The resulting leaks or blockages in the cooling system can potentially lead to overheating and reduced battery life.

Underbody and Frame:

Just like traditional vehicles, EVs have underbody components such as the chassis, suspension, and brake components that are susceptible to corrosion, especially if the vehicle is driven in areas where roads are salted during winter. Corrosion can weaken the structural integrity of the vehicle.

Engineering Update 12

Electrical Contacts and Connectors:

Electrical connectors and contacts throughout the vehicle can corrode, leading to issues with sensors, lights, and other electrical systems. This can affect overall performance and safety.

Material Longevity:

EVs often incorporate a variety of materials, including metals and alloys, in their construction. Corrosion can significantly reduce the lifespan of these materials, leading to premature failure of crucial components. Protecting against corrosion ensures the durability and reliability of the vehicle over time.

Safety Concerns:

Corrosion can compromise the structural integrity of a vehicle, posing safety risks for occupants. In an EV, where advanced technologies and high-voltage systems are prevalent, maintaining structural integrity becomes even more critical. Proper corrosion protection helps mitigate these concerns.

Performance and Efficiency:

Corrosion on electrical components, connectors, and conductive elements can hinder the performance and efficiency of an EV. For instance, corrosion on battery terminals may increase electrical resistance, leading to reduced energy transfer efficiency and overall performance. Ensuring corrosion-free connections is vital for maintaining optimal efficiency.

Cost Savings:

Corrosion-related damage can result in expensive repairs and replacements. By investing in effective corrosion protection measures, manufacturers and owners can avoid these costs, contributing to the overall economic viability of electric vehicles.

Environmental Impact:

EVs are often considered more environmentally friendly than traditional vehicles. However, if corrosion leads to premature scrapping of EVs or frequent replacement of components, it can undermine their environmental benefits. Proper corrosion protection helps maintain the longevity of EVs, reducing their overall environmental impact.

Maintaining Resale Value:

Corrosion damage can significantly reduce the resale value of a vehicle. As EVs become more common in the used car market, maintaining corrosion protection becomes essential for preserving the value of these vehicles over time.

Regulatory Compliance:

Different regions have regulations and standards regarding vehicle safety. Corrosion protection is often a requirement to meet these standards and ensure that EVs adhere to guidelines.

Aesthetic Considerations:

Corrosion can also affect the appearance of a vehicle. For EV manufacturers who emphasize design and aesthetics, ensuring that the vehicle maintains its visual appeal over time is crucial for customer satisfaction.

To mitigate and address corrosion issues in EVs, manufacturers take the various measures, including the use of corrosion-resistant materials, applying protective coatings and sealants to prevent moisture and salt exposure, regular maintenance and warranty coverage. It’s important for EV owners to follow manufacturer recommendations for maintenance and care, as well as be aware of their local environmental conditions. Proper care and maintenance can help reduce the risk of corrosion and ensure the longevity and safety of the vehicle. Additionally, addressing corrosion issues promptly can prevent them from becoming more serious and costly problems in the long run.

In summary, implementing corrosion protection measures for electronic vehicles should be based on specific circumstances and environmental conditions. Corrosion protection is fundamental for the long-term performance, safety, and sustainability of electric vehicles. It addresses not only technical and safety considerations but also contributes to the overall economic and environmental viability of EVs in the automotive market.

Engineering Update 13

SuperCORR A specialist barrier film corrosion protection

EnviroTech Europe supplies advanced corrosion protection products, based on approved synthetic materials, to provide quality solutions to a diverse range of lubrication and corrosion problems.

SuperCORR A is a unique and proprietary formulation with long-lasting, anti-corrosion inhibitors providing a superior lubrication coefficient and protection against moisture, wear, general and fretting corrosion, static electricity, corona, and other electro migration problems. The non-flammable film is only 7 microns (0.007mm) in thickness, is not a wax or oil-based product and is formulated without sulphates, chlorides, petroleum-based material, or halogens, to meet the EU RoHS directive. The use of SuperCORR A for corrosion protection can not only bring financial savings in reduced maintenance and replacement costs but more importantly greater safety. It is much simpler and a lot less costly to prevent corrosion than to repair or replace the damaged equipment or component that failed because of corrosion.

SuperCORR A is packaged in aerosol cans making access to component parts easy for engineering crews in difficult locations and conditions. Unpainted mild steel will not rust on exterior surfaces directly exposed to sea water environments for at least 6 months, protecting electrical connectors, switches, chains, drive shafts from corrosion while maintaining lubrication on moving surfaces.

EFFICIENT AND ECONOMICAL

• Extremely long-lasting, specially formulated and proprietary anti-corrosive inhibitor.

• Eliminates premature failure of components created by moisture, general or fretting corrosion.

• Prevents deterioration and contamination on all surfaces of electronic and electrical equipment and mechanical close tolerance moving components.

• Reliability increased, maintenance intervals increased and costs reduced, manufacturers save costly warranty service calls or product re-call.

HISTORY

SuperCORR A was originally developed for the U.S. Air Force to comply with military specifications and to prevent electrical and electronic components from systems failures caused by corrosion. It became the industry standard for avionic corrosion protection within MROs (maintenance, repair and operations) and OEMs (overhaul and original equipment manufacturers). It’s unique ability to displace water and provide a performance enhancing level of corrosion protection has led to it being used in many other applications and industries worldwide.

FURTHER INFORMATION

Please visit our website

www.envirotech-europe.com/supercorr-a for information about other uses and applications for SuperCORR A.

For more advice, please telephone us on +44 (0) 20 8281 6370 or use our website contact form.

All products are supplied and supported by EnviroTech Europe Ltd. Manufactured in the United Kingdom and available on short delivery times through our dedicated team of distributors worldwide.

Supplied and supported by EnviroTech Europe Ltd Aissela, 46 High Street, Esher, Surrey, KT10 9QY, United Kingdom

Tel +44 (0) 20 8281 6370 | www.envirotech-europe.com | contact@envirotech-europe.com

Engineering Update 14

optimas.com

Prototyping to Elevate Output Engineering to Optimize Inventory Quality Planning & Testing In-House Quality Services Ep 4: Quality & Engineering Contact Optimas so our Expert Engineers can find ways to Save Costs, Boost Performance, Reduce Risks Distributing & Manufacturing Fasteners since 1892 Optimas Toolbox Talks Coming Soon!

ENGINEERING & QUALITY SERVICES

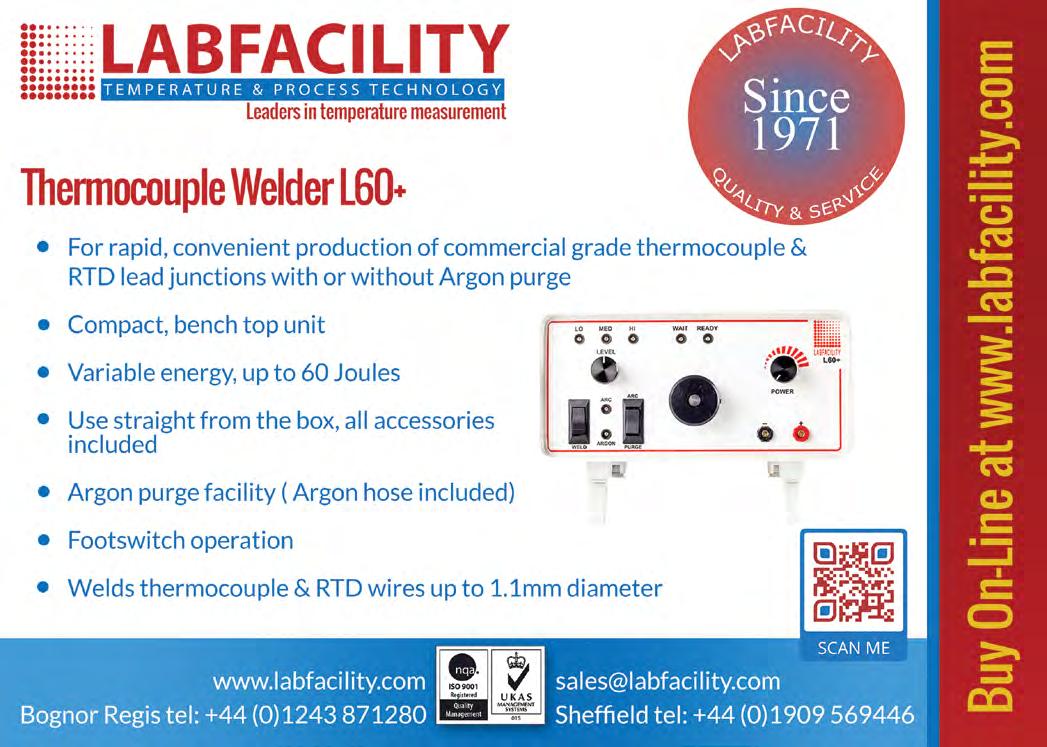

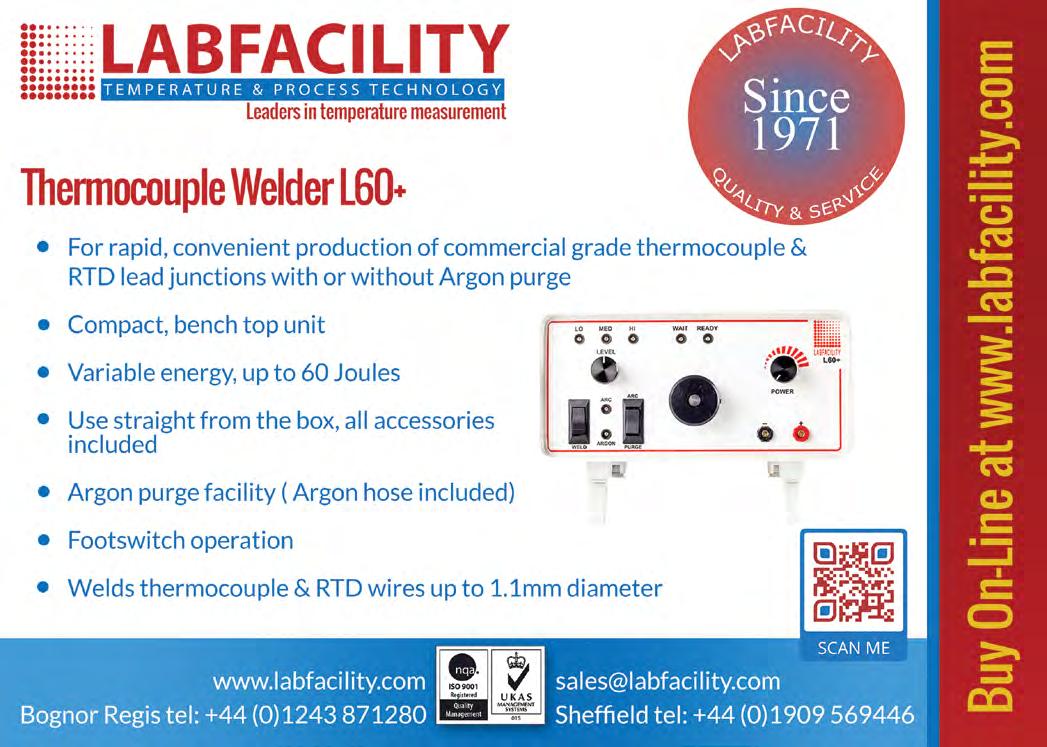

L60 Thermocouple Welder

Understanding the L60 Thermocouple Welder

Before diving into the benefits of the L60 thermocouple welder, let’s first address the question:

What is a thermocouple welder? A thermocouple welder is a specialised device used to join the ends of thermocouple wires together to create a reliable and accurate junction. This junction is crucial for accurately measuring temperature in various applications, ranging from industrial processes to scientific research.

Spotlight on the L60 Thermocouple Welder

The L60 Thermocouple Welder is a compact, simpleto-use instrument designed for thermocouple and fine wire welding, offering a range of features tailored to meet the diverse needs of users:

• Precision Welding

• Versatility

• Ease of Use

• Durability

• Comprehensive Accessory Kit

Conclusion: Manufacture Your Temperature Sensing with Confidence

The L60 Thermocouple Welder epitomises precision, efficiency, and reliability in temperature instrumentation. With streamlined operations, cost-saving benefits, and versatile applications, the L60 welder enables users to achieve accurate measurements with ease. Whether in industrial settings or scientific research, the L60’s precision welding ensures consistent and reliable thermocouple welding. Its robust construction and longevity guarantee durability and providing long-term stability. Furthermore, the L60’s repeatability ensures precise results every time. With the L60 thermocouple welder, experience unmatched precision and reliability.

Engineering Update 17

Click here for more information.

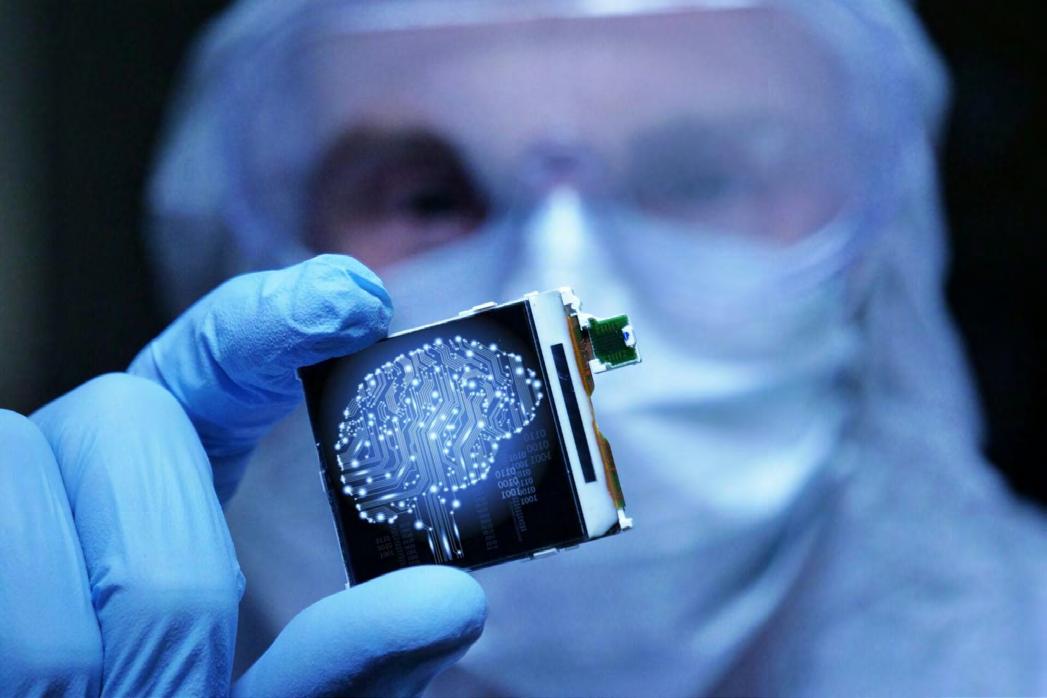

From parts to perfection

Automation needed to handle the world’s smallest devices.

The manufacturing of micro medical devices, with their increasingly complex geometries and tiny dimensions, presents unique challenges to manufacturers. When the final product is only millimetres wide, the internal minuscule scale of the components involved must be manufactured at the microscale, often being invisible to the naked eye. Here, Tom Cash, director of Siemens parts supplier Foxmere, explains why OEMs should automate high precision assembly.

Early this year, researchers at the Brigham and Women’s Hospital developed a grain-sized implant called The Micra™, a heart-implanted pacemaker.

The implant delivers nano doses of anti-cancer drugs directly into a patient’s brain tumour, which not only enhances precision but also reduces invasiveness too, with the size of the pacemaker being that of a vitamin capsule.

The iStent inject®, one of the world’s smallest medical implant, is also inserted during cataract surgery and remains within the eye to alleviate intraocular pressure.

This innovative device offers a minimally invasive option for managing eye pressure, and is particularly beneficial for conditions like glaucoma, ensuring ongoing relief and improved patient recovery.

However, manufacturing micro medical devices with intricate geometries, like the world’s smallest pacemaker, the Micra™, requires specialised approaches because of components that are just millimetres in size, and wires that are just .002 inches.

Engineering Update 18

Material selection

Assembling microdevices goes beyond the dimensional accuracy of parts. As objects diminish in size, micro and nanoscales introduce substantial changes in surface-to-volume ratios, altering chemical and material properties.

Consider micro-electromechanical systems (MEMS), which are crucial components in biomedical applications. At these minute scales, MEMS face challenges such as heightened friction, shifts in thermal conductivity and increased sensitivity to external forces.

These transformations have a direct impact on the reliability of MEMS, particularly in applications like microfluidic components, implantable drug delivery devices and neurostimulators.

To tackle these challenges, manufacturers must meticulously choose materials and employ microfabrication techniques. Photolithography, etching and electroplating are all processes used to shape and structure materials accurately on a minuscule scale, making them ideal for the precision required for microdevices.

Spotting defects

What’s more, the medical device industry is governed by stringent quality standards and regulations, such as the Medicines and Healthcare products Regulatory Agency (MHRA), which is responsible for regulating the UK medical devices market to ensure they are safe and effective for their intended use.

Adhering to rigorous standards, the manufacturing of micro medical devices covers all stages of production, spanning from the initial design to the final part inspection.

Here, quality management systems must guarantee that every minute component aligns with required specifications and tolerances, ensuring precision and quality for all medical applications.

For example, Ultra-HD cameras capture detailed images that use AI and advanced algorithms analyse irregularities or specific attributes in real time.

The use of highly sensitive sensors, such as micro-scale cameras, accelerometers or pressure sensors, can also be integrated into medical devices to monitor and detect micron level defects.

ROI

With that in mind, assembly usually stands out as the most financially demanding phase in bringing a device to market. Yet not many manufacturers realise that return on investment (ROI) through automation can be a strategic advantage.

In the initial planning phase of microdevice manufacturing, attention to material selection, component costs and process validation is common, but we find that many underestimate manufacturing and assembly costs.

In fact, according to Techreviewer, robotic process automation in healthcare helps to reduce operational costs by nearly 50 per cent. In addition, the report also claims that automation helps to recover costs in a short period.

Partnering with a reliable automation parts supplier with expertise in high precision assembly, like Foxmere, is essential for manufacturers wanting to navigate their way through the complexities of microdevice manufacturing.

In a sector that demands accuracy, quality and adherence to industry standards, manufacturers must be able to lean on a trusted parts supplier, especially as groundbreaking innovations — like the Micra™ and the iStent inject® — require a more customised approach.

To find new, reconditioned or obsolete parts for medical device manufacturing, regardless of whether it’s a 20-year-old system or the latest automation technology, please visit the Foxmere website.

foxmere.com/en

Engineering Update 19

The Fusion of Robotics, AI, and AR/VR: A 2024 Revolution in Manufacturing.

In 2024, the manufacturing industry is currently at the doorstep of a transformational era, one marked by the seamless integration of robotics, artificial intelligence (AI), and augmented reality/virtual reality (AR/VR). This fusion is not merely a technological trend but a paradigm shift reshaping how materials are produced, processes are optimized, and workers interact with machinery. Today’s technologies are reshaping how these advanced technologies are evolving manufacturing, ushering in an era of unprecedented efficiency, innovation, and competitiveness.

Robotics and automation for manufacturers

Robotic automation has long been a cornerstone of modern manufacturing, streamlining repetitive tasks, enhancing precision, and augmenting human labor. However, recent advancements in robotics have elevated their role from mere tools to intelligent collaborators. Powered by AI algorithms, these robots possess the ability to adapt, learn, and optimize operations in real-time. Whether it’s assembly line tasks, material handling, or quality control, robotic systems equipped with AI are changing the speed, accuracy, and flexibility of production processes.

Leveraging intelligent technologies

The Intelligence of Artificial Intelligence is a key component. AI is the driving force behind the cognitive revolution in manufacturing. By harnessing vast amounts of data generated throughout the production lifecycle, AI algorithms can uncover insights, predict outcomes, and optimize operations with unprecedented precision. From predictive

maintenance and demand forecasting to supply chain optimization and resource allocation, AI empowers manufacturers to make data-driven decisions that drive efficiency, minimize downtime, and enhance overall productivity. Moreover, AI-driven analytics enable manufacturers to unlock new levels of customization and personalization, catering to the diverse needs and preferences of consumers.

The use of data isn’t enough to power this evolution, and manufacturers are also realizing the importance of bridging the physical and digital worlds. AR/ VR technologies are blurring the lines between the physical and digital realms, offering immersive experiences that revolutionize manufacturing workflows.

The role of AR/VR to power AI and robotics

On the shop floor, AR-powered smart glasses provide workers with real-time visualizations, instructions, and contextual information, enhancing training,

Engineering Update 20

troubleshooting, and task execution. VR simulations, on the other hand, enable manufacturers to design, prototype, and optimize products in virtual environments, minimizing costs, accelerating time-tomarket, and fostering innovation. By leveraging AR/ VR, manufacturers can transcend the limitations of traditional manufacturing methods, unlocking new possibilities in design, collaboration, and customer engagement.

What sets this technological revolution apart is not just the individual advancements in robotics, AI, and AR/ VR but their synergistic convergence. When integrated seamlessly, these technologies create a holistic ecosystem that amplifies their individual capabilities, leading to transformative outcomes across the manufacturing value chain.

For instance, AI-driven robotics can collaborate with human workers in real-time, guided by AR visualizations that provide insights and instructions, resulting in unparalleled levels of efficiency, quality, and safety.

How generative AI creates additional benefits

And when it comes to AI, today’s Generative AI technologies are giving even more power to manufacturers. ChatGPT is the latest technology driven by AI that uses natural language processing. It leverages deep learning algorithms to enable users to converse with chatbots. What has captured the attention of manufacturers, designers and engineers is that it is an advanced system that can understand complex questions and provide very accurate answers almost immediately.

Because it was developed with conversational AI capabilities, it can immediately comprehend user queries and generate natural-sounding responses that are tailored to the conversation context. It also has built-in memory capability that stores information from past conversations to better respond to subsequent messages.

Today’s leading manufacturers are building AImodels like ChatGPT to help create virtual worlds in the metaverse to run simulations and increase productivity/efficiency metrics. More specifically, AI tools like ChatGPT and the metaverse can help create a 3D environment that replicates the real world, and the data used can be harnessed for analysis, running simulations and interacting with data more efficiently.

The use of robotics, AI and AR/VR in manufacturing streamlines operations, reduces costs, and increases productivity by enabling access to advanced technologies without the capital expenditure and technical complexities of setting up and maintaining these systems internally. This deep level operational strategy allows today’s manufacturers to focus on their core competencies while leveraging the benefits of automation. Combined with other advanced technologies such as AR/VR, AI and IoT, manufacturers across a number of industries will realize true competitive advantages and become category leaders of tomorrow.

This fusion of robotics, AI, and AR/VR is reshaping the manufacturing landscape, heralding a new era of innovation, efficiency, and competitiveness. By harnessing the power of these advanced technologies, manufacturers can unlock unprecedented levels of agility and customization, driving sustainable growth and prosperity in an increasingly dynamic global economy. As we stand on the cusp of this transformative journey, embracing collaboration, innovation, and responsible stewardship will be paramount in realizing the full potential of this technological revolution.

About The Author: Dijam Panigrahi is Co-founder and COO of GridRaster Inc., a leading provider of cloud-based AR/VR platforms that power compelling high-quality AR/VR experiences on mobile devices for enterprises. For more information, please visit www.gridraster.com.

Engineering Update 21

5 Digital Trends That Are Revolutionizing the Oil and Gas Industry

The UK is facing a growing global energy crisis, which is driving up oil and gas prices. This is a major challenge for consumers and gas and oil companies alike, who are struggling to meet demand.

Digital innovation is essential for the oil and gas industry to succeed in the face of increasing pressure. By adopting a digitalfirst approach, companies can alleviate the oil and gas crisis and work more efficiently.

In this article, hydraulic torque wrench manufacturer we will explore five digital trends and innovations that the oil and gas industry can benefit greatly from.

The Rise of Robotics and Automation

Working within oil and gas industry workers can often be exposed to hazardous materials, extreme temperatures, and confined spaces. In recent years, there has been a growing focus on safety in this industry, and robotics and automation are playing a major role in this effort.

Frost & Sullivan reported that the global gas and oil automation market is growing rapidly due to two key reasons:

– To overcome COVID-19 – To meet the growing need for efficiency, sustainability, and safety

The global gas and oil automation market is expected to reach £18.69 billion by 2025. This represents a staggering increase of 43% since 2020. The market is also growing at a compound annual growth rate (CAGR) of 7.5%.

Digital Equipment Testing

Oil and gas sites are inherently dangerous. While there are safety measures in place, such as efforts to eliminate hazards and providing workers with personal protective equipment (PPE), there is always room for improvement.

Regular safety examinations of systems can help to prevent accidents. This is because they can identify potential hazards and risks before they cause harm.

Enerpac’s Safe T™ Torque Checker is a device that can be used to validate and test the exact torque equipment used on-site. This includes the pump, wrench, and hose. The checker provides a precise digital readout of the torque, which can be used to ensure that the equipment is operating correctly and safely.

The performance and safety of an entire system can be instantly validated with digital equipment testing. This minimizes the chance of errors and incidents by identifying and addressing potential problems before they occur.

All-in-one data analytics tools

In the gas and oil industry, massive amounts of data are generated on a daily basis, which play a critical role in day-to-day operations.

Engineering Update 22

Data is essential for many industries, as it provides powerful insights into production and performance. These insights can then be used to optimize processes, develop AI-driven algorithms, and improve performance.

The Power of Laser Scanning and 3D Printing

Sourcing complex, customized stand-alone parts can lead to extended downtime for oil and gas companies. This is a major issue in the industry, as it can result in significant revenue losses.

One way to reduce downtime by months and optimize operations is to laser scan every part of the impeller 3D models and 3D print metal fabrications.

As a result, companies can enjoy greater precision, insight into potential problems, and shorter planning times.

Sensors on the ring collect data that is then analyzed by cloud-based solvers. This process can help identify safety risks within the reservoir and provide new insights into structural design.

Adopting digital innovation can significantly help oil and gas companies overcome current challenges and stay ahead in a competitive market.

In addition, current digital trends can help improve operational efficiency, enhance worker safety, and reduce critical costs.

This can be achieved simultaneously with improving processes and technology.

Engineering Update 23

NORD at Passenger Terminal Expo 2024 in Frankfurt

The drive specialist will present its airport logistics solutions.

NORD DRIVESYSTEMS has specially optimised a product series from the LogiDrive solutions space for the requirements of airport logistics. The specialist will present its drives at the leading trade fair for the airport and air transport industry from 16 to 18 April 2024.

Luggage items of different weights often have to be transported over long distances: This places very special demands on the drive technology. NORD has specially optimised a product series from its LogiDrive solution space for applications such as tray, belt or roller conveyors. The three system solutions are all lightweight and feature compact installation space, but also provide different advantages:

LogiDrive Basic

• Consists of an IE3 asynchronous motor, the decentralised NORDAC ON frequency inverter and a gear unit from the NORD portfolioo Convinces with low investment costs and a wide adjustment range

LogiDrive Advanced

• Consists of an IE5+ synchronous motor, the decentralised NORDAC ON+ frequency inverter and a gear unit from the NORD portfolio o Operates with high energy efficiency, saves CO2 emissions and also allows for a variant reduction

LogiDrive Advanced with DuoDrive

• Consists of the DuoDrive geared motor and the decentralised NORDAC ON+ frequency inverter

o Provides the advantages of the LogiDrive Advanced plus low maintenance effort

LogiDrive Advanced and LogiDrive Advanced with DuoDrive are especially advantageous in large conveyor systems with numerous drive units. The particularly efficient drive solutions enable enormous savings in terms of energy costs and therefore also CO2 emissions. The reduction of various drive variants in a large system also reduces costs. A variant reduction minimises administrative costs and streamlines production, logistics, storage and service processes.

Furthermore, NORD supports its customers in finding the most energy-efficient drive solution for their individual application. The NORD ECO service checks installed drives with regard to energy efficiency, dimensioning and number of variants. Based on this analysis, customers receive an energy efficiency concept that is entirely tailored to the requirements of the respective application.

NORD DRIVESYSTEMS will present its drive solutions for airport logistics from 16 to 18 April 2024 at Passenger Terminal Expo in Frankfurt. You will find the company at Stand D300.

Engineering Update 24

Our 2024 Brochure now available

Advanced solutions for vapour degreasing, corrosion protection, metal cleaning and surface treatments

Our products are used in the following industries:

EnviroTech Europe are specialists in metal cleaning and corrosion protection solutions.

We offer a range of approved products tailored to your industry, which are cost effective, energy efficient, safe for operators and the environment.

We are pleased to introduce our range of products in our 2024 products brochure: www.envirotech-europe.com/brochure

• Electronics and Electrical

• Environmental

• General Cleaning

• Industrial and Manufacturing

• Marine and Maritime

• Mechanical Engineering

• Medical Device Manufacturing

• Military

• Motorsport

• Power Generation

• Railways and Automotive

Engineering Update 12

Engineering Update 26

London Packaging Week Innovation for entries

The

inaugural LPW Innovation Awards

aim to celebrate

UK

market disruptors and their transformative pursuits.

Organisers Easyfairs launched the London Packaging Week Innovation Awards today, seeking to highlight the businesses that use innovation to shape the packaging landscape.

Over the next three months, companies will be able to apply for their innovative products to be judged by a dedicated jury comprising some of the leading lights in the world of packaging design and innovation and representatives of some of the biggest global brands. The jury will search for packaging creations that challenge the accepted limits of what is possible, showcase new technologies or techniques, and inspire the next generation.

The LPW Innovation Awards have been designed to inspire the next big idea and to encourage advancements in sustainability and performance across four industry sectors. Ingenious up-and-comers and well-established brands will compete for their most innovative commercialised packs to be judged by expert juries.

Innovation Awards open

Engineering Update 27

Standout names on the respective juries include Michael Carroll, Senior Packaging Specialist at Nestlé; Jim Bligh, Corporate & Public Affairs Director & Communications Leader at The Food and Drink Federation; Tanguy Pellen, Partner at Skarbek; Cain Hayward-Hughes, Senior Global Creative Manager – Prestige at Beam Suntory; Chris Allinson, Group Packaging Leader at PZ Cussons; Alfredo Ruiz Pose, Head of Purchasing at Glenmorangie, and renowned packaging expert Raphael Ferri.

Chris Allinson said: “I was delighted to be asked to join the jury panel at London Packaging Week to champion the remarkable achievements within our industry while fostering a culture of recognition and appreciation for our peers’ daily contributions. Those of us in R&D often operate behind the scenes, yet our efforts are instrumental in driving progress and innovation. This event provides a platform to shine a light on our collective endeavours.”

Cain Hayward-Hughes added: “I have long admired luxury packaging [both professionally and personally] in the spirits industry; the ability of well-designed and executed packaging to tell the unique stories wrought by the people who craft the spirits at each distillery is endlessly fascinating. There is such depth and breadth to what luxury packaging can do to elevate a brand, a story, an emotion – that to be part of a jury celebrating these achievements is an opportunity for me to give back to the industry I admire so much.”

Entries, which are free of charge, are invited from brands, design agencies, and suppliers with the clients’ authorisation across four key categories: Premium & Luxury Drinks, Beauty Cosmetics & Perfume, Food Beverages & Personal Care and Fashion Accessories & Jewelry, with the first submission deadline for the inaugural LPW Innovation Awards already confirmed as Friday, May 17.

Engineering Update 28

“We know firsthand that innovation is alive and well, and nowhere is it more prevalent than in the packaging sector,” said Christelle Anya, Content & Community Director at Easyfairs, and a driving force behind the awards. “For as long as I can remember, the industry has been evolving rapidly, and you only have to walk the floor of one of our UK shows to understand a little more about the pace and scale of the change and progress in the industry. This innovation excites us, and as we continue to see packaging manufacturers grow alongside us and their products take the world by storm, we feel it is high time we recognise these efforts.

“It would be a reasonable observation that a significant proportion of the current innovation addresses sustainability concerns and the circular economy. Brand owners, big and small, are delivering exceptional packaging experiences, often against all the odds, and they still innovate and excite customers, all while delivering revenue, differentiation, and quality to brands. Packaging and the packaging value chain always find a way, and so do we. Our motivation for the awards was to create a true celebration of market

disruptors and their transformative pursuits.”

Prospective entrants must meet a minimum of one of four key criteria to enter: (Innovation) Technology GameChanger, (Design) British Design & Craftsmanship, Consumer experience (British Experiential Quality), or Sustainability Impact (Environment Game-Changer).

From transformative, technical or process-driven innovations linked to the consumer experience to emotional connections and eco-credentials, winners will receive their awards on the second and final day of London Packaging Week 2024.

Products should be distributed in the UK market between May 25, 2023, and May 24, 2024, and a full breakdown of the qualifying criteria and all other guidance on submitting your entry can be found here.

Engineering Update 29

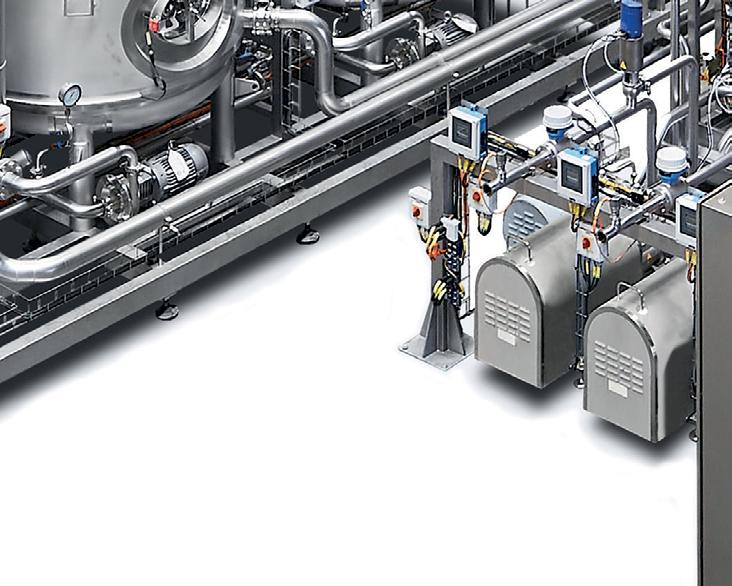

HRS Heat Exchangers operates at the forefront of thermal technology, offering innovative and effective heat transfer products worldwide, focusing on managing energy efficiently

Wastewater

Sludge

Digestate

Waste streams from: Agriculture, Food, Pharmaceutical and other industries

HRS Heat Exchangers | +44 (0)1923 545 625 | info@uk.hrs-he.com | www.hrs-heatexchangers.com